2 min read

How to Prevent Injuries From Hydraulic Hose Failures

Python Covers Team

:

Jun 11, 2021 12:00:00 AM

One of the most dangerous situations for hydraulic equipment is a hose burst. A hydraulic hose burst could be a pinhole leak or a full hose burst. in either situation, not only is the operator at risk for injury but so is the equipment.

A hydraulic hose failure can be regulated with maintenance checks, but that doesn’t guarantee a hose assembly won’t fail. Investing in the right products can protect equipment, lower costs, and ensure operator safety.

Article contents:

- How Hydraulic Hoses Fail

- Effects of Hydraulic Hose Failure

- How to Protect Yourself from Hydraulic Hose Failure

- Practice Safety First

How Do Hydraulic Hoses Fail?

Hydraulic hoses burst for a number of reasons. The first step towards preventing catastrophic hose failure is understanding and identifying the causation behind it.

Hydraulic hose failure typically occurs for these four reasons:

- Tube Erosion causes external leakage

- Hydraulic Fluid is set to the wrong temp, pressure, etc.

- Improper Assembly or Size can result in failure at the fittings

- Abrasion can create wear and tear to the hose

To prevent hose bursts, all hydraulic hoses should be suitably positioned, supported, and given physical protection.

Equipment that operates at as little as 100 PSI can have leaks that puncture human skin and cause severe damage. Hydraulic equipment operates at very high working pressures, often at 3,000 PSI and higher, allowing for extreme damage if not careful.

When a person's skin gets punctured after a hydraulic line burst, it may only feel like a small prick. However, the fluid seeps deep under the skin into the bloodstream, muscles, and tendons. Within a short period of time, the wound may begin to throb and burn on the inside of the skin.

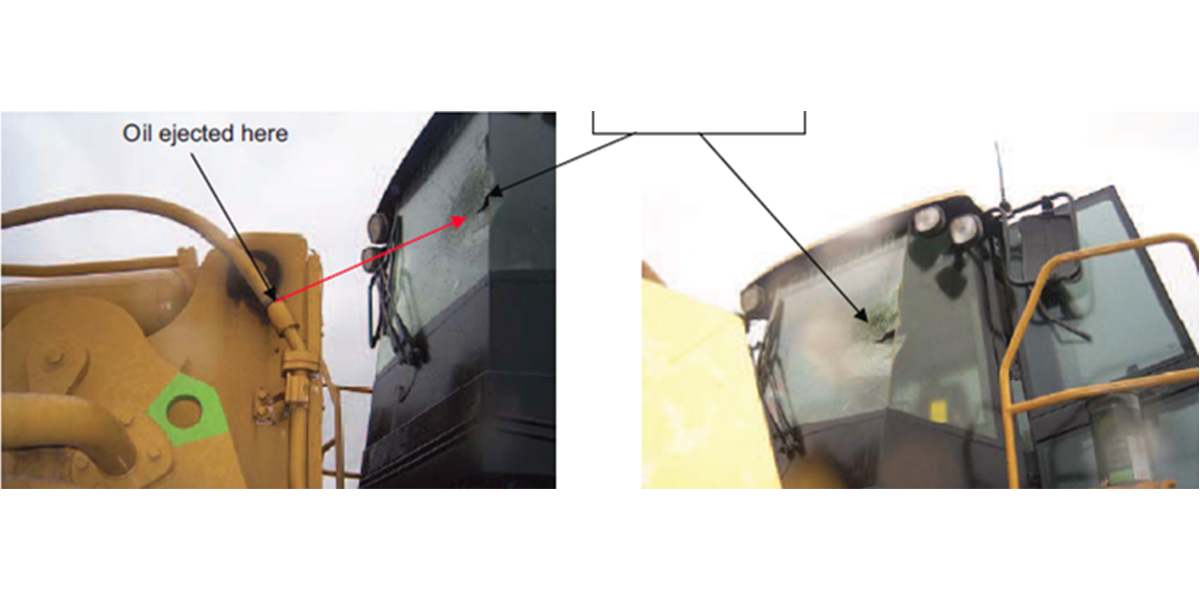

Since the fluid from the broken assembly is hot and highly pressurized, the injury could result in amputation or death if a medical doctor doesn’t remove the fluid within a few hours after injection. Here you can see the result of a hydraulic system failure and the consequences of an untreated oil injection.

Hydraulic Hose Burst Protection

Python Protective Sleeve + Covers offer a revolutionary hydraulic hose sleeve to keep your workers and equipment safe in potentially abrasive environments. The Diamondback PRO is pinhole tested to 4,000PSI and burst protection tested to 12,000PSI. If a hose were to break, the sleeve would hold the fluid inside, reducing the risk of costly injuries and workers comp claims.

The Diamondback PRO sleeve is constructed using proprietary engineered fiber, woven tightly, and heat-treated to shrink the sleeve to the finished dimension, reducing oil spillage. The Diamondback Pro sleeve also reduces sleeve installation by up to 80% and is 50% less bulky than Cordura.

Protect Yourself Before It's Too LAte

Hose failures can cause an extreme amount of damage. Hoses and equipment can always be replaced, but equipment operators cannot. Ensure you’re taking the necessary safety precautions such as using protective sleeves to prevent injury and damage in the event of a hose failure.

For more information on the capabilities of our Diamondback sleeve, or to find out where to purchase a batch, contact Python for more information.